Safe reuse of medical material

MED-T-COAT: Nanotechnology-based coating to prevent biological/microbial contamination to enhance MDs reprocessing.

TECNAN (Spain)

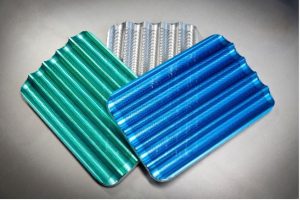

Currently, a large part of the health centers use surgical instruments labeled by the manufacturer as single-use material. This material, on the recommendation of the manufacturer, should be discarded through its initial use, becoming a biohazard waste. In this context, the need for financial savings of health centers and the ecological awareness that has increased in recent years, unleashed the reutilization of this material (In 2012, 45.2% of European hospitals with more than 250 beds, according to the FDA, performed this practice). This is defined as the use of a MD, more times than those specified by the manufacturer on the label and is normally preceded by reprocessing and remanufacturing, which includes all the steps taken to convert a contaminated single-use device into a device ready to be used in another patient. These stages are the following: washing, functionality tests, packaging, labeling and sterilization. Reprocessing is foreseen in the new EU legislation on MDs, (Article 17).

TECNAN is a company with a wide experience in the field of developing functional and easy to apply nanocoatings addressed for different substrates. These functional nanocoatings provide properties as non-corrosive, anti-reflective, non-stick, water repellence, easy-to-clean and/or antimicrobial and antiviral properties, among others. These nanotechnology-based products and their applications have been completely optimized at industrial scale in different sectors as renewable energies, automotive or food, among others.

Medical sector is of great interest for TECNAN and Safe-N-MedTech project is the gateway to validate these typologies of functional nanocoatings in this field. To do so, MDs have been evaluated and surgical instruments of different materials have been selected and treated showing good results. Since, some of their nanocoatings have been applied to confirm the potential use of this technology to enhance reprocessing chances for the MDs and it was found that easy-to-clean properties were achieved. This situation would facilitate the cleaning processes in the reprocessing of the material. Reducing infections and wastes at the same time. Antibacterial properties are also interesting for other surfaces, being synergistic with Pilot test case 2.

Nevertheless, to assess efficacy of the functional coatings and the possibility to reuse MDs, the proposers need OITB services according to the current stage of development, including regulatory, assessment of existing data, evaluation of the potential of nanoparticles leakage, biocompatibility, surface integrity and sterility, production and/or business model. All this with the aim to respond questions regarding the possibility of the use of nanocoatings in the medical sector, the definition of the materials that fit better for the best application, the revision of the current regulatory requirements and/or the evaluation of the functionality.

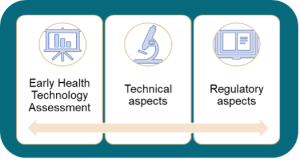

In this sense, a close collaboration between partners has allowed the development of an action plan involving: i) an early evaluation of the health technology, to study important issues related with the ensure of the safety and efficacy, the cost estimations, the evaluation of the social acceptance and/or the reduction of the environmental impact due to reuse of MDs; ii) the definition of technical aspects, including physico-chemical characterization, efficacy, safety and processability evaluation and iii) a revision of current regulatory aspects, describing steps to be followed for MDs reuse.

To do so, TECNAN has established a close collaboration with other partners as TECNALIA, SINTEF, CIBER, IPCIM or STAMI, among others with the aim to select materials used in medical sector and to define application procedures and analysis to be carried out. More in detail, more than 500 samples have been treated and distributed between partners to be used as materials for physic-chemical characterization and y studies in terms of cytotoxicity, biofilm formation and antimicrobial activity.

So far, nanocoatings have been fully characterized in terms of physico-chemical properties employing different technologies of microscopy as scanning electron (SEM) or atomic force (AFM), fluorescence and thermoanalytical or thermomechanical analyses. Revealing the presence of a uniform deposited layer in treated samples with a created nanotexture at the grain boundaries.

Evaluation of the antibacterial capacity has been carried out according to normative ISO 22196 where Escherichia coliCECT 516 and Staphylococcus aureus CECT 240, a Gram-negative and Gram-positive strain were used as model organisms. More in detail, control and test surfaces are inoculated with bacteria and, after 24 hours of incubation, microbial concentrations are determined. Preliminary results show, against both strains, an antibacterial activity higher than 2. It means that, samples that incorporate the TECNAN’s nanocoating with non- stick and antibacterial properties show antimicrobial activity against Escherichia coli (99,94%) and Staphylococcus aureus (99,37%).

By its part, the evaluation of biofilm grown inhibitory capacity has been realized under ASTM E-2647 standard to evaluate the growth of biofilm of Pseudomonas aeruginosa and other species. More in detail, Pseudomonas aeruginosa CECT 116 and Staphylococcus aureus CECT 240, a Gram-negative and Gram-positive strain were used as model organisms. The experiments have concluded that in all cases, the results indicate that biofilm formation on treated surfaces was reduced compared to the non-treated controls. These preliminary results that show reduction from 60% to 99% reduction in biofilm formation even without employing biocides, represent an important advance for the application of nanocoatings from TECNAN in the medical sector and others.